M process

M process

1) MOLDING

The feedstock is printed using a special press (similar concept to theplastic injection).

The product of the molding is a solid structure (mixed metal powder/resin) called Green Body, dimensionally increased according to a shrinkage factor variable for each League.

DEBINDING 2)

Printed components (Green Body) is placed in the oven to be catalytic debinding: the Elimination of the Binder (de-binding) will cause a reduction of the weight of the component.

The weak solid structure composed of aggregates of dust is called Brown Body.

At this stage there is no dimensional change but the only weight loss (due to loss of resin component).

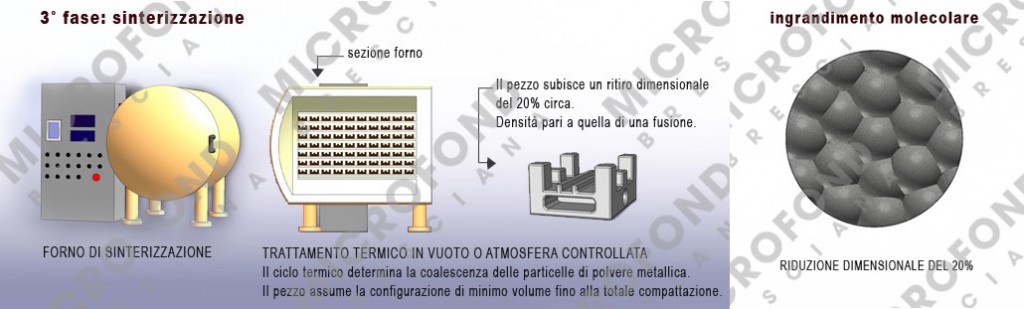

3) sintering

Deletes the resin, the components are placed in a special sintering furnace.

Specific thermal cycles in vacuum or controlled atmosphere cause the coalescence of metal dust particles.

The piece takes the minimum volume configuration up to total compaction.

The acquisition of the mechanical characteristics and dimensions are measurable by the final density and the

dimensional shrinkage (around 20%): the piece is completely analogous to a derived from fusion.